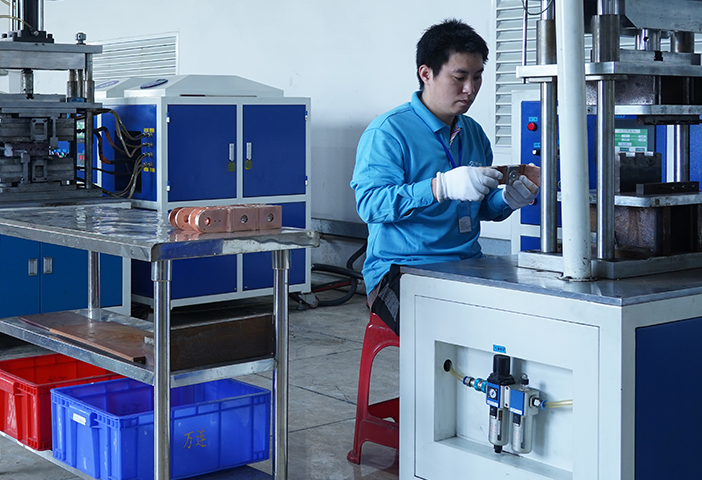

Well-linking Manufacture Capability

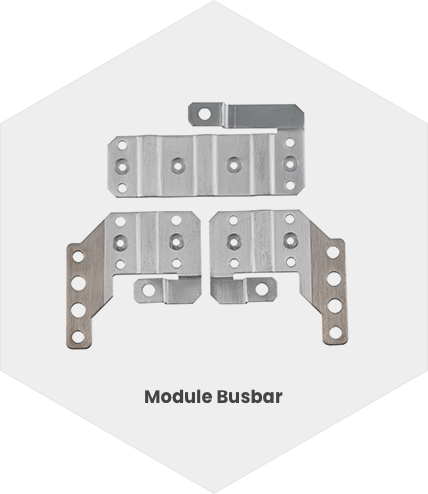

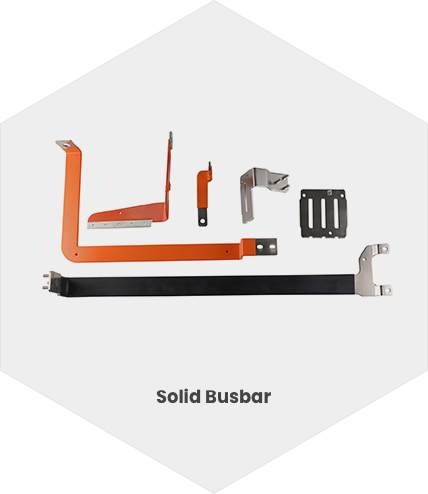

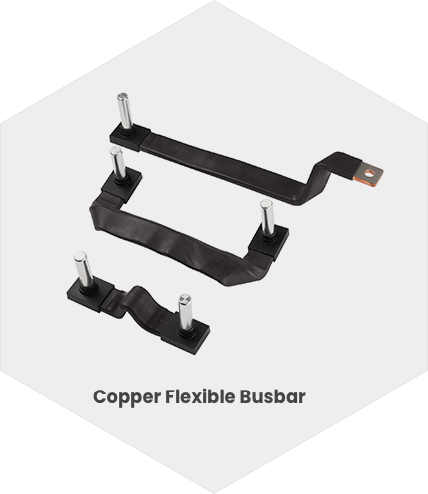

Provide Full range of busbar for all cell-types battery pack

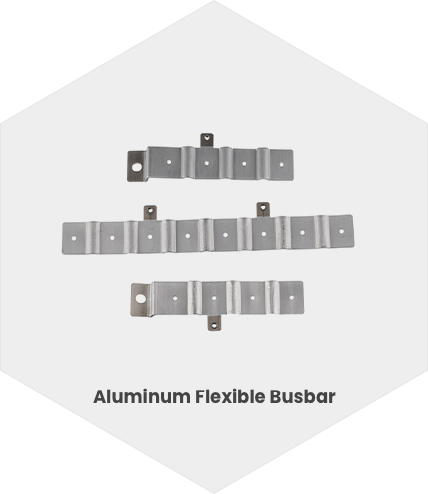

Provide full range of different type busbar

Provide a wide range thickness busbar: 0.4mm-20.0mm

Use advance welding technology for busbar manufacture

Use reliable manufacture process qualified by oversea customers

Apply new technology/process for busbar manufacture

Use advance test equipment to monitor and control busbar quality